|

|

| Flur

|

Bookmarked for

later.

same

|

Love not the world, neither the things

that are in the world. If any man love the world, the love of

the Father is not in him. - 1 John

2:15 | | |

| egypt

|

Plenty of religious imagery

is ok for the new world airport. But, it is not ok to

display the 10 Commandments outside of a courthouse. Go

figure.

Love, e

|

|

| | |

|

|

| TahoeBlue

|

TBM's for airports ...

think Denver...CSM BESSAC develops and uses a range of

TBM’s designed to excavate in all type of geological

conditions, from highly-permeable terrains to the hardest

rock, under heavy water pressure. - PDFhttp://tunnellingjournal.com/news/rocksy-cracks-halfway-mark-%E2%80%93-press-release/Rocksy

hits halfway – press release By Tris Thomas on

February 17, 2011  The first breakthrough of one of the two

12.45m diameter Herrenknecht EPBMs working on Brisbane’s 6.7km

long Airport Link project has occurred deep underground at

Wooloowin, marking the halfway point of the machine’s 2.5km

journey to Lutwyche. “Australia’s largest TBM,

Rocksy, has already excavated over 1,200m of tunnel since she

was launched at Kalinga Park in July,” announced Minister for

Infrastructure and Planning Stirling

Hinchliffe. “Considering that this time last year

pieces of the machine were being shipped to Brisbane from

Germany, this shows great progress on the

project.” Minister Hinchliffe congratulated

Rocksy’s tunnelling team who have worked tirelessly towards

today’s successful breakthrough. “Working around

the clock, seven days a week, the TBMs have progressed at

rates of up to 110m a week, digging the tunnels and lining

them with concrete segments as they go,” Mr Hinchliffe

said. “Across the project, over 9km of tunnels

have been completed, with the TBMs Rocksy and Sandy alone

having excavated more than 2.2km. “ Over

300,000 cubic metres of spoil has been generated by the TBMs

and transported to Nudgee Road via a 2km spoil conveyor,

eliminating almost 40,000 spoil truck movements from local

streets in Clayfield. “This is a terrific outcome

for locals and commuters using those roads.” ... Thiess

John Holland Project Director Gordon Ralph said the second

TBM, Sandy, was expected to break through into the Kedron

caverns next month, with both TBMs scheduled to complete their

2.5km journey by the middle of the year. “Once

tunnelling is complete the cutterheads for the massive TBMs

will be buried underneath the tunnels they have created,” Mr

Ralph said.

“The two TBMs were custom built for

the Airport Link project and this solution will reduce the

complexity involved in removing the cutterheads, while

avoiding the need for additional surface work in the Lutwyche

area.” BrisConnections CEO Dr Ray Wilson said

today’s breakthrough brought the team one step closer to the

operation of Airport Link in mid-2012. “More than

70% of the project is now complete and when Airport Link opens

in mid-2012, it will be the first major motorway connecting

Brisbane city with the airport and northern suburbs,” he

said. ”It will improve travel times, providing six

new lanes for drivers between Bowen Hills and Kedron and four

new lanes between Kedron and Toombul.” | - - -

http://suppliersandequipment.mining.com/2008/06/17/giant-gaskets-seal-underground-highway-tunnel/Giant

gaskets seal underground highway tunnel Written by

InfoMine - Mining Equipment and Supplier News, June 17th,

2008  In Madrid, Spain, an underground highway

tunnel In Madrid, Spain, an underground highway

tunnel will help reduce traffic congestion. Like moles,

two massive tunnel boring machines have inched their way

forward, leaving a walled tunnel behind. Gaskets from

Trelleborg provide a waterproof seal between the massive

tunnel ring segments. ... One of the many solutions in

the project was a 3,650- meter highway tunnel that crosses the

city center underground, less than 6.5 meters away from a busy

subway line at certain points. Finished in mid-2007, the M30

“Bypass South-East” has three lanes in each tunnel and

sidewalks on each side. At the time of its construction, the

excavated dimensions of the tunnel, 15.2 meters in diameter,

were the largest ever required. This demanded an entirely new

breed and size of tunnel boring machine, also called a TBM or

“a mole.” “Two machines were used, one at each

end of the tunnel. TBMs are usually custom-made for each

individual tunnel project,” says Erwin Brakenhoff, Sales

Director, Trelleborg

Bakker in the Netherlands. “Costing in the millions

of dollars, a TBM has the advantage over other methods in

terms of safety and timing; in addition, it is extremely

precise, which in turn, reduces the cost of lining the tunnel.

This makes TBMs more suitable for use in built-up

areas.” Alfredo Avello, Director of Abyo, a

supplier of tunneling equipment in Spain, calls the M30 tunnel

project a team success. “This project was led by Madrid

Municipality, and two joint ventures formed by leading Spanish

contractors excavated the tunnels. In addition, other highly

qualified Spanish contractors executed very important

complementary surface works,” says Avello. “It has also been a

pleasure to work with Trelleborg, which supplied gaskets for

sealing the segments in both tunnels.”

|

|

| | |

| TahoeBlue

|

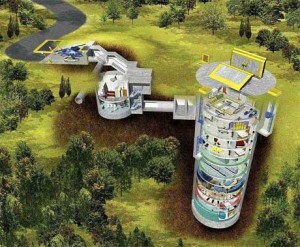

http://www.hardenedstructuresofamerica.com/about.html Hardened Structures of America Hardened Structures of America is a

Professional Construction Program Management Company, partners

of Hardened Structures and Hardened Shelters, LLC,

specializing in the confidential planning, design and covert

construction of fortified homes, bomb shelters, underground

shelters, homes with underground bunkers, survival shelters,

2012 Shelters, bu nkers and hardened military

facilities. These facilities are designed for

sustainability with independent sources of power and water and

incorporate numerous defensive and offensive capabilities.

They can serve as a primary dwelling, vacation home, corporate

retreat, long term shelter or expanded multi-function

compound. Client confidentiality and total project secrecy are

paramount on all of our projects. Hardened

Structures of America can provide all designs, planning,

estimating, engineering, modeling, construction and technical

support to offer complete turn-key survival facility solutions

for private/residential, commercial, military and special

projects. Hardened Structures can also provide all of the

specialized equipment necessary for underground bunker

construction, CBRE air filtering systems, blast doors, blast

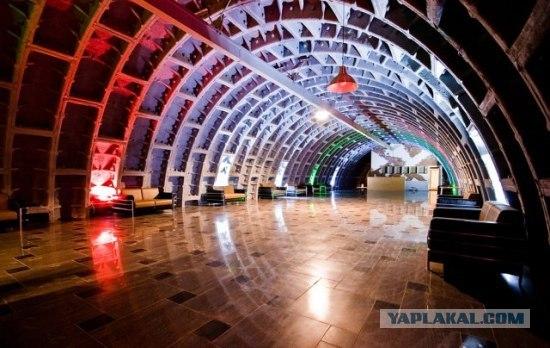

valves, water generators, etc. http://englishrussia.com/2010/10/09/bunker-42-in-taganka/Bunker-42

- Taganka  The Cold War Museum (exhibition complex

Bunker-42) is a military historical museum and an entertaining

complex founded in t he former classified military object of

the USSR – Alternate Command Center of Long-Range Aviation

(GO-42). The territory of the museum represents an

underground bunker with an area 7000 m2 located 60 m deep

near Taganskaya metro station. The museum has been working

since 2006 after Bunker-42 was bought from “Rosimuschestvo”

at the auction by “Novik Service” company.  In the 1960s the object was equipped

with everything necessary in the case of nuclear attack. In the 1960s the object was equipped

with everything necessary in the case of nuclear attack.

Later, in the middle of the 70s, there was made up a decision

about its reconstruction. In 1995 the object was totally

declassified. In 2006 “Novik-Service” purchased the object for

2,166,700 USD and started its restoration. Only massive

armoured doors and steel sheathing of the walls remind about

the former classified object. More:http://picturesofmoscow.com/tag/sport/In

2006, the secret signal office centre, located at a depth of

60 meters and has an area 7000 square meters has been sold to

a private company. Now Soviet history is open to

visitors. The Red Bull company has spent today in

the bunker selection round of the World championship of

football freestyle. ... video's Top secret bunker

«Tagansky»

|

|

| | |

| TahoeBlue

|

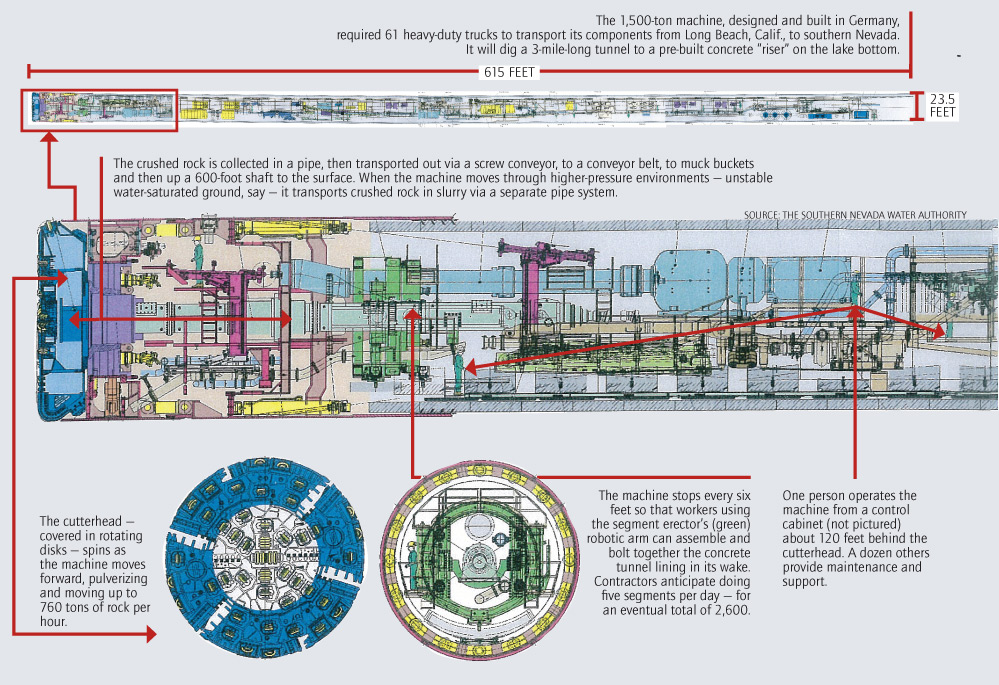

http://www.hcn.org/issues/42.10/a-boring-diagram June 07, 2010 issueby Sarah Gilman

Lake Mead -- Las Vegas' primary water supply -- has

been drawing down like a leaky tub over the past decade,

thanks to prolonged drought in the Colorado River Basin. The

reservoir's now at 43 percent of capacity and about 100 feet

below full -- just 45 feet above one of two main water

intakes. If projections pan out, the water level could drop

below that intake's pumping system by 2013. So the Southern

Nevada Water Authority plans to spend the next three years and

a total of $610 million digging under and up through the

reservoir's bottom with a

custom tunnel boring machine to build a new water

intake, 190 feet below the one that must be replaced, and

connect it to the existing water system. http://arizonageology.blogspot.com/2011/09/tunneling-under-lake-mead.html Monday, September 05, 2011 Tunneling

under Lake Mead Las Vegas is digging a 1,500

foot long tunnel, 600 feet below ground through bedrock to

suck water from Lake Mead, in case the lake level drops

too low for the existing intake to draw water. "Intake No. 3

will maintain SNWA's ability to draw upon Colorado River water

at lake elevations as low as 1,000 feet above sea level,

assuring system capacity if lake levels fell low enough to put

Intake No. 1 out of service." [right, Intake 3 tunnel. Credit,

SNWA] The starter tunnel is complete, ready for the

boring machine to be lowered into it for assembly. An earlier

starter tunnel was abandoned after it hit a fault zone and

unstable rock. SNWA has a short video explaining the

project. http://www.snwa.com/apps/video/index.cfml?cid=36&vid=139http://constructionnew.blogspot.com/2011_10_01_archive.htmlSaturday,

October 29, 2011 Herrenknecht TBM Gets Ready To

Drill Under Lake Mead  ... Southern Nevada's newest piece

of mega-hardware—a custom $25-million Herrenknecht

tunneling-boring machine—will make its long-awaited

underground debut later this year. The machine works

like a giant mechanical earthworm, gnawing through dirt, rock

and muck while forming a protective tunnel that will

eventually channel raw Colorado River water onto nearby

treatment plants before the water is pumped to homes and

businesses throughout the Las Vegas valley. The

1,800-ton, 600-ft-long TBM is the workhorse of a

$526.6-million third raw-water intake tunnel project at Lake

Mead, 30 miles southeast of Las Vegas. A joint venture of S.A.

Healy Co., Lombard, Ill., and Impreglio S.p.A., Sesto San

Giovanni, Italy, known as Vegas Tunnel Constructors (VTC) LLC,

is the design-build contractor. The additional intake is

needed because the lake has dipped 100 feet since 2000 amid a

decade of drought and boom growth. The TBM will

carve out a three-mile-long, 20-ft-dia reinforced tunnel under

Lake Mead that draws water at 860 feet. That depth is

deeper than the other two intakes, which may soon become

inoperable if water levels continue to fall. The drill

head, which rotates in 16 different positions, is already

underground. The five-piece TBM should be fully assembled by

early December, with commissioning to follow.It

has been a long, hard road to reach this point.

Herrenknecht’s Schwanau factory in southern

Germany took 17 months to design and manufacture the

machine, which was shipped in five large pieces to

California’s Long Beach Harbor and then transported to the

jobsite outside of Boulder City, Nev., in 61 truckloads. The

transportation feat took months of planning and coordination,

mapping out the route and securing special heavy-haul permits.

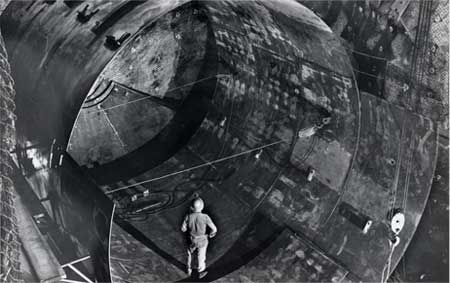

In 2010, an intake starter tunnel flooded

three times in six months, prompting the construction team to

abandon its original alignment and drill in a drier direction,

roughly 23° northeast from the problematic tunnel along a ½°

uphill slope. The move increased project costs by 15% and

pushed the completion date back two years, to 2014. As

it stands, the TBM is being lowered piecemeal down a

30-ft-dia, 600-ft-deep access tunnel using a head-frame-gantry

system with dual 200-ton strand jacks. It took crews 32 hours

to lower the 315-ton drill head. "There

was only three to four inches clearance on either side,"

explains Jim Nickerson, VTC deputy project

manager.

|

|

| | |

| TahoeBlue

|

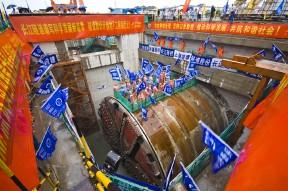

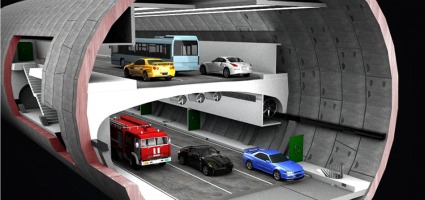

http://www.herrenknecht.de/http://www.herrenknecht.de/produkte/tunnelvortriebsmaschinen/traffic-tunnelling/mixschild.html http://www.waterworld.com/index/display/article-display/340838/articles/waterworld/projects-contracts/herrenknecht-tunnel-boring-machines-reach-targets-in-shanghai.html http://www.waterworld.com/index/display/article-display/340838/articles/waterworld/projects-contracts/herrenknecht-tunnel-boring-machines-reach-targets-in-shanghai.html SHANGHAI, China, Sept. 19, 2008 -- Two

Herrenknecht tunnel boring machines, the largest in the world

with a diameter of 15.43 meters, successfully completed their

crossing beneath the Yangtze River in Shanghai. SHANGHAI, China, Sept. 19, 2008 -- Two

Herrenknecht tunnel boring machines, the largest in the world

with a diameter of 15.43 meters, successfully completed their

crossing beneath the Yangtze River in Shanghai. On May 28

and September 5, 2008, the two Mixshields met their target

shafts precisely on the Yangtze River island Changxiang -- far

ahead of schedule. The 7,472 meter long tunnels connecting the

Shanghai district of Pudong with Changxiang island have

created efficient transport systems in only 20

months. The Herrenknecht Mixshield S-318, one of

the two largest tunnel boring machines (TBM) in the world with

a diameter of 15.43 meters, reached its target shaft on the

Yangtze river island Changxiang on September 5, 2008. But not

only this giant showed a top performance, excavating an almost

7.5 kilometer long tunnel tube in highly water-bearing

construction ground in only 20 months. A good three months

before, on May 28, 2008, the identical Herrenknecht Mixshield

S-317 reached its target shaft with great precision. Using the

two high-tech giants from Schwanau, the shell of the two

parallel running large diameter tunnels, which are scheduled

to be opened for car and subway traffic for the 2010 World

Exhibition, could be completed 10 and 12 months ahead of

schedule respectively. Shanghai,

China In May and September 2008 the two world

largest tunnel drilling machines - two gentleman farmhand

mix sign with 15.43 meters of diameters - locked the

propulsion under Jangtse river successfully in Shanghai. After

20 months 7.5 kilometers of combined road and Metrotunnel were

finished in the carcass. One year in former times than planned

reached the giants their goal on the Fluss-Insel Changxing.

Thus the chances stand well that the two parallel tunnel tubes

can be transferred to traffic punctually to the world fair

2010 in Shanghai. http://www.herrenknecht.com/fileadmin/redaktion/PDF_Downloads/S-317_S-318_Shanghai_Folder_GB_09-03-11.pdfNEW

MILESTONE: BIG SUCCESS IN SHANGHAI. THE WORLD’S LARGEST

TUNNEL BORING MACHINES CROSSED BENEATH THE YANGTZE

RIVER. The largest Tunnel Boring Machines worldwide.

Herrenknecht provided two 15.43 meter diameter Mixshields to

excavate two 7.47 kilometer-long parallel tunnels, which cross

beneath China’s largest river, the Yangtze. The Yangtze River

is one of the country’s busiest waterways. To avoid

impediments to vessel traffic, mechanized tunnelling was

preferred over an immersed tunnel or bridge construction in

the very busy south channel of the Yangtze River. The twin

tunnels are located at a depth of up to 65 meters in

groundwater-bearing sand, clay and broken rock formations. The

multi-functional tunnels will have two levels: the upper deck

will be used as 3-lane road tunnel. The lower deck will serve

as service and rescue tunnel. The longterm objective is to

also use the lower deck for metro traffic by integrating the

Shanghai Rail Transit Line 9. Dongtan – the first

planned eco-city. The world’s first eco-city is to be

created in the middle of the Yangtze River delta. This pilot

project for Chinese environmental policy will be realized on

the island of Chongming off Shanghai in the coming years. The

planned eco- city will be built according to the strictest

environmental standards. Dongtan will have the most up-to-date

environmentally-friendly technology. From waste recycling

and water treatment – still far from standard in China to

supplying heating and electricity from renewable energy

sources. However, the planners are going a couple of steps

further; they want to restrict car traffic to the periphery of

the residential areas, which is why their transport planning

is oriented towards pedestrians and cyclists. They plan to

locate working and living close enough to each other to make

energy-consuming commuter traffic unnecessary. The

residential blocks are planned with no more than 8 stories,

including their greened rooftops. The ambitious plan of the

British engineering studio Arup and the Shanghai Development

Company SIIC is to complete the initial phase in time for the

World Expo 2010. Some 80,000 people from various social

backgrounds are expected to live in Dongtan by the year

http://www.herrenknecht.com/news/press-section/none-bigger-tunnel-boring-machine-for-orlovski-tunnel-brings-new-world-record.htmlNONE

BIGGER: TUNNEL BORING MACHINE FOR ORLOVSKI TUNNEL BRINGS NEW

WORLD RECORD.  In early July 2011, the Russian operator

company NCC (Nevskaya Concession Company) placed an order with

Herrenknecht – the TBM manufacturer, based in Schwanau,

Germany – for the construction of a Mixshield. The tunnel

boring machine (TBM) for the Orlovski Tunnel will surpass all

previous TBMs. With a diameter of 19.25 m, the tunnelling

shield, designed to link both halves of the center of St.

Petersburg under the River Neva, sets a new world

record. St. Petersburg,

Russia / Schwanau, Germany, 17 August 2011. On the occasion of

the contract signing for the world’s largest tunnel boring

machine, entrepreneur Martin Herrenknecht recently met the

Russian Prime Minister, Vladimir Putin, in St. Petersburg. In

a high-level business meeting, Mr. Putin wanted to find out at

firsthand about the gigantic automobile tunnel project – an

extremely challenging construction project under the River

Neva, which will be carried out using the world’s biggest

tunnel boring machine. The contract for the

manufacture of a 19.25 m diameter Mixshield, which smashes all

previous diameter records, had previously been signed by

the Russian operator company, NCC (Nevskaya Concession

Company) and Herrenknecht AG. For Herrenknecht, this is the

biggest single order in the company’s history and represents a

huge technical challenge, which has been well prepared by

extremely thorough, intensive preparatory engineering

collaboration between the customer and the

contractor. Including the backup, the

Herrenknecht Mixshield will be a total of 82 meters long. On

its own, the tunnelling shield will weigh around 3,800 tons

and deliver 8,400 kW drive power to the cutting wheel. The

leap in diameter to 19.25 m will enable the machine to

excavate 600 cubic meters of soil hourly. The excavation

area is more than 50% larger than that for the largest TBM

currently in operation in the world (see list of record

holders below). A Mixshield is the quickest and safest

solution for driving the around 1 km long tunnel bore under

the Neva in the face of the high groundwater pressures. An

extremely ambitious timetable has been set for implementation

of the project. Tunnelling is set to begin in St.

Petersburg in the spring of 2013, with the tunnel due to be

taken into operation in 2016. The aim of this new

and world’s largest mechanically bored tunnel is to provide

significant relief in the center of St. Petersburg and allow a

continuous traffic flow in the city divided by the

river. http://www.cowi.com/menu/NewsandMedia/News/BridgeTunnelandMarineStructures/Pages/st-petersburg-to-build-worlds-widest-bored-tunnel.aspxSt

Petersburg to build world’s widest bored tunnel

|

|

| | |

| TahoeBlue

|

http://www.popsci.com/category/tags/tunnel-boring-machine A Race Against Time To Complete New

Delhi's Newest Subway Line A Race Against Time To Complete New

Delhi's Newest Subway Line By Sandeep Ravindran Posted

02.10.2010 at 11:23 am A worker stands inside one

of the Metro tunnels under construction in New Delhi, India,

in preparation for the Commonwealth Games this October. To

overcome the challenges of a tight three-and-a-half-year

schedule and construction underneath a densely populated city,

engineers used 14 tunnel-boring machines (TBMs) to dig the

underground thoroughfarehttp://www.thehindu.com/news/cities/chennai/article2731213.eceTunnelling

will throw up debris, and challenges too With the city receiving its first batch of

Tunnel Boring Machines that will be used to build the Metro

Rail network's underground section, it is only a matter of

time before massive subterranean holes begin to take shape

beneath the surface. ... But much of the ‘pain' would be

due to underground station construction. Tunnelling, on the

other hand, would have little or no impact at the surface

level. Chennai Metro Rail Limited Managing Director

K.Rajaraman says that people will not even know that holes are

being drilled beneath the surface. Out of the 11

TBMs that would eventually be in operation, the first one

would be launched from Washermenpet. The tunnelling

would be controlled by precision electronic systems. The

cutting rotor (shield) of each TBM would also be supported by

a 78 metre long trailing assembly, consisting of components

that provide mechanical support and help remove the excavated

material. To put it simplistically, the TBM works

similar to an earthworm with cycles of digging forward and

dragging the rear end afterwards. A series of hydraulic

systems push the TBM forward (excavating the soil), while the

rear end of it is braced against the tunnel wall. When the TBM

head has excavated to its maximum length, the ‘shield' and the

rear end is pulled forward

|

|

| | |

| TahoeBlue

|

http://www.groundwateruk.org/Groundwater-Issues-Radioactive-Waste-Disposal.aspx One of the experimental galleries at a

depth of 420m in SKB’s underground research laboratory

at Aspo, Sweden. Rob Cuss © NERC 2008  Tunnel boring machine driven incline

from the 420m to 440m levels in SKB’s underground

research laboratory at Aspo, Swede Tunnel boring machine driven incline

from the 420m to 440m levels in SKB’s underground

research laboratory at Aspo, Sweden. The laboratory

is constructed in granodiorite. Rob Cuss © NERC

2008  Driving a new experimental gallery at a

depth of 490m in the Bure underground

research

laboratory in the eastern Paris Basin, France. John Powell

© NERC 2009 Deep geological radioactive waste

disposal in other European Countries While

progress towards a solution for the long-term management of

the United Kingdom’s radioactive waste has been progressing

over the last 8 years, internationally some projects are now

at an advanced stage. In Europe, Finland is

developing an underground characterisation facility at

Olkiluoto, known as the ONKALO, which has now reached a

depth of about 320m. If ONKALO confirms that the site meets

all the safety case criteria for the development of a

repository, a facility will be developed at the site with a

planned commencement of disposal operations around 2020.

Sweden has evaluated two potential sites for the

disposal of spent fuel, one near Forsmark and the other near

Oskarshamn, and in June 2009 announced that their

preferred site for the development of a repository was that at

Forsmark. They also have constructed and operate the Äspö

underground hard rock laboratory, near Oskarshamn, that is

used for full scale in-situ testing of different

technical solutions in a realistic repository environment and

have operated an ILW disposal facility at Forsmark for

20 years. Both Belgium and France have underground

research laboratories and are close to deciding where

their disposal facilities will be located. All of these

countries have worked in partnership with the local

communities and have a high level of support from them for

their projects.

|

|

| | |

| TahoeBlue

|

http://www.frieze.com/issue/article/tunnel_vision_pendle/Tunnel

Vision Informant A new exhibition about New York’s

underground earth works reveals a quasi-mythological mirror

image of the city  Workers are lowered into the Tunnel

Boring Machine Launch Area, 26th Street and 11th Avenue, New

York (2008... . ‘The Future Beneath Us’,

currently on show at the New York Transit Museum Gallery

Annex, and at the Science, Business and Industry Library,

speaks of a mirror city to New York, a benighted, unglamorous

metropolis of dark shafts and damp thoroughfares in which air

is hewn out of rock, rather than rock heaped into air. It

paints this portrait quite accidentally while describing the

eight massive subterranean construction projects currently

taking place deep beneath the city’s surface. The

simultaneous creation of a thicket of tunnels, hubs and work

plants has seemingly resulted in an alter-city being formed, a

sunless empire hidden entirely from the view of most of the

city’s denizens. Chief among the projects is the

gargantuan Water Tunnel No. 3, one of the largest engineering

projects in the world. It has a diameter of seven

metres, stretches for almost 100 kilometres, and reaches

depths beneath the city of over 250 metres, as deep as the

Chrysler building is high. It is a work of monumental size and

beauty, a gargantuan concrete tube laid down amidst a

glistening backdrop of quartzofeldspathically-banded

garnetiferous muscovite-biotite schist. The only shame is that

it will never be seen. Its entombment is part of its creation.

It is a true earth work.

|

|

| | |

|

|

| TahoeBlue

|

http://www.pixpow.com/general/amazing-tunnel-machine/http://tunnellingjournal.com/news/855/ Italian tunnelling specialist SELI has

celebrated its 60th Anniversary Italian tunnelling specialist SELI has

celebrated its 60th Anniversary by manufacturing a

400-ton, 6.18m diameter DSU TBM painted gold, for the

Kishanganga tunnel project in India. The gilded machine

was delivered to the main contractor HCC (Hindustan

Construction Company) today during an official ceremony at the

company’s factory in Aprilia. The DSU TBM will bore

700-1000m under the Himalayas, crossing critical geological

conditions of localised poor and squeezing rock as well of

fault zones. The TBM has been specially designed to cope

with the ground conditions and improve them through extensive

pre-treatment works. ... The company was founded by

Mr. Carlo Grandori in 1950, and it was he who introduced

mechanised TBM excavation technology to Italy in 1969 and,

alongside Mr. Dick Robbins, designed and manufactured

the first Double Shield TBM. SELI claims to be

the only company in the world that acts as TBM manufacturer

and TBM tunnelling contractor, with experience of 800km of

tunnels in over 100 projects all around the

world. The new SELI factory under completion

in Aprilia (Rome) will boost the TBM production capacity from

today’s 8 units per year to over 20 units, with boring

diameters exceeding 15m diameter. http://secondavenuesagas.com/2010/05/14/down-the-rabbit-hole-a-tunnel-boring-machine-comes-alive/Down

the rabbit hole, a tunnel boring machine comes

alive By Benjamin Kabak  For the first time since the April 2007

groundbreaking, the MTA invited reporters and city officials

underground to mark another Second Ave. Subway

milestone. Today, at shortly after 10:30 a.m., MTA CEO and

Chairman Jay Walder blasted an air horn that marked the

start of the tunnel boring machine’s journey from 92nd St. to

63rd St. With two City Council members and a House

representative along for the photo op, the MTA reaffirmed its

commitment to Phase 1 of the Second Ave. Subway and stressed

the December 2016 completion date.

|

|

| | |

| TahoeBlue

|

http://www.blippitt.com/gotthard-base-tunnel-ahead-of-schedule-photos/ Gotthard Base Tunnel Ahead of Schedule

(PHOTOS) Sept 2009The Gotthard Base Tunnel now

being drilled out beneath the Alps Gotthard Base Tunnel Ahead of Schedule

(PHOTOS) Sept 2009The Gotthard Base Tunnel now

being drilled out beneath the Alps, the

longest underground tunnel ever constructed, came

one step closer to completion earlier this month when another

two sections were connected. Tunnel boring

engineers broke through the last several feet of rock between

Erstfeld and Amsteg near the northern end ... http://www.blippitt.com/gotthard-base-tunnel-another-breakthrough/The

main section of the Gotthard Base Tunnel is 34 miles long

and connects northern and southern Europe, said

AlpTransit Gotthard company in a prepared

statement. The world’s longest tunnel should become

operational at the end of 2017,” the statement

said. The company says the tunnel is an

environmental feat and will allow millions more tons of

items to pass through the Alps by rail. “Only

by upgrading its railway infrastructure can Switzerland meet

the rising demand for freight transportation and the

increasing needs of customers,” the statement

said. High-speed trains moving at speeds of up

to 155 mph will greatly shrink travel times between Zurich,

Switzerland and Milan, Italy. The tunnel

is currently scheduled to open in 2017. It will be a total

of about 95 miles long when completed. http://www.vectorsite.net/g2007m08.html... Surprisingly,

problems arise not because the rock is too hard but because

it is, in places, too soft, like butter, complicating the

digging and slowing it to a crawl. The problems have caused

the price tag to almost double, and the tunnel is not expected

to be finished before 2018.  * In related news, an article on BBC WORLD

Online ("Africa & Europe Set For Tunnel Link" by Richard

Hamilton) says the governments of Spain and Morocco are now

in discussion towards plans to put a railway tunnel beneath

the Straits of Gibraltar.

|

|

| | |

| TahoeBlue

|

http://www.tunneltalk.com/Dick-Robbins-Mar09-Franklin-Medal-winner.php Dick Robbins receiving his

award Dick Robbins receiving his

award... Richard J. Robbins, President and

CEO of The Robbins Company from 1958 to 1993 is to receive the

prestigious Benjamin Franklin Medal for Engineering. Dick

is being honored for his career dedication to the development

of tunnel boring machine technology and the application of

TBMs for some of the largest and most challenging tunneling

projects in history. Dick joins an illustrious list of

previous recipients including, Albert Einstein, Thomas Edison,

Stephen Hawking, and Jane Goodall. http://www2.fi.edu/press/images-and-media/awards/2009/bios/09/robbins.pdfRichard

J. Robbins President The Robbins Group, LLC Seattle,

Washington The 2009 Benjamin Franklin Medal in

Engineering is presented to Richard Robbins for

his

imagination and skill in developing a hard-rock tunnel

boring machine and its associated

systems, resulting in a

safe, economical, and efficient method for constructing

tunnels.From man’s first invention of gun powder,

explosives were used to blast through rock and ground to

make tunnels. This dangerous process, used to build new roads

or mines, remained largely-unchanged until the 1950s

when Dick Robbins helped bring an entirely different kind

of

rock-cutter to the world’s attention – enabling for the

first time such massive projects as digging

a tunnel under

the English Channel. Through the family tunnel drilling

company, Robbins

produced Tunnel Boring Machines [TBM]

that could economically, efficiently, and safely

bore

through not only hard rock, but also through changing

terrain or terrain pressurized with water.While he had

competitors, it was Robbins who provided the first truly

viable TBMs, ushering in an era of rapid,

cost-effective, and safe tunnel construction. Robbins

earned his B.S. in mechanical engineering from Michigan

Technological University in 1956. Just two years after he

graduated, he took over the family’s tunneling company upon

the untimely death of his father. In addition to the

difficulty of trying to keep the company running, Robbins

focused on refining his father’s ideas for a new rock boring

machine. He substituted hard disks for the drill bits that

kept breaking; he added hydraulic pistons to increase the

pressure and help fragment the rock; he developed ways to

remove the rock without having to stop drilling; and he

ultimately even added maintenance shops and crews’ quarters to

the giant machines. He gained a reputation in the drilling

community for providing machines that could tackle the most

difficult projects, safely and inexpensively, and for being

someone who could constantly dream up new improvements and

then actually build them. ... http://www.convertingtoday.co.uk/story.asp?storycode=13042Carlo

Grandori October 2002 By Dick Robbins, friend

and collaboratorThe international tunnelling

community has lost one of its most innovative and productive

personalities. Carlo Grandori, founder of Societa Esecuzione

Lavori Idraulici (SELI), died on 17 September at the age of

91. I was privileged to attend the service in Rome where many

of his friends and colleagues gathered to remember his

life.Carlo Grandori was a industrial engineer

who specialised in hydroelectric construction and large dams.

After World War ll, he concentrated on the tunnelling and

underground aspects of this specialty and became known as an

expert in traditional rock tunnelling. In the early 1960s

he participated as a joint venture partner in machine

tunnelling projects with his friend and TBM pioneer, Duri

Prader, in Zurich, Switzerland. I first met Carlo

when he visited Seattle in 1967. He was planning a bid for the

Orange-Fish project (T&TI, May 1969) in South Africa and

was considering the possible application of a tunnelling

machine. Although a machine was not chosen for this project,

Carlo and his engineers continued to look for a machine

tunnelling job they could sponsor. After a complicated

negotiation with ENEL, SELI was awarded the 4.5km

Brasimone-Suviana Tunnel near Bologna, Italy, in about 1970.

The rock in the 6.4m diameter tunnel was unstable and

complicated and required immediate support. Carlo initiated

the design of interspersing steel ribs with precast segments

as close as possible to the front of the tunnelling machine.

This started a trend in Europe of using precast segments in

rock tunnels that would eventually extend to many other parts

of the world. The unstable rock face led Carlo to suggest

modifications to the cutterhead, which was the first attempt

at rotary breasting or active support of the face while

boring. It was clear to Carlo Grandori that tunnel

boring machines were in the early stages of development for

bad rock conditions. In-the-tunnel modifications would be

required to adapt the machines to the rock, as it became

apparent how the rock was reacting to the tunnel opening being

bored. This initiated a life long collaboration for me with

Carlo and his team. In 1972 I brought to Carlo the

idea of a telescoping shield machine with grippers located in

the aft shield so that segments could be set while the boring

was in progress. Carlo was intrigued and immediately began

to sketch improvements to the concept. He realised that

driving a machine through the rock was only one element of a

successful job. Erecting supports, advancing infrastructure

services and hauling out the muck were equally important

tasks. The activities supporting the machine advance provided

great potential for improving the efficiency of machine

tunnelling. In 1972 SELI secured the Orichella and

Timpagrande tunnels in Calabria, a 4km long, 4.3m diameter,

complex of tunnels in partly decomposed granite. This was to

be the first application of a double shield tunnelling

machine. Carlo Grandori spent many days in his tunnels

watching the machines and their trailing equipment perform. He

was an active innovator and as a result the SELI double shield

jobs performed with better results than could be achieved by

other contractors. After his son Remo had completed his

engineering studies and military commitments he joined the

SELI firm and gradually took on larger responsibilities in the

machine and tunnel engineering work. Carlo shifted his

concentration to unique designs of trailing or 'backup'

equipment and segment installation. Some years and many

double shield machines later, SELI collaborated with Prader on

the 7.5km long Langeten Relief Tunnel (1988-1991) in

Switzerland where a double shield machine installed hexagonal

segments for the first time. Carlo utilised this experience to

design the backup system for the Yindaruqin Irrigation

Project in China (T&TI, June 1991). This design

proved to be a major step forward. The machine, operating in

relatively favourable rock conditions, advanced 1,200m to

1,300m per month, while installing the hexagonal precast

segmental lining. This job led to a long series of successful

tunnel jobs in China. Carlo remained active in the

design of backup systems until quite recently. He designed a

system for the Manabi project in Ecuador, which was only

recently completed. The tunnel achieved an average advance of

64m per day. Carlo's technical contributions and

leadership in the field of tunnelling will be missed by the

entire industry. However, he was quite successful as a mentor

and teacher to many people who can carry forward his design

concepts and creative problem solving in

tunnelling. Carlo's health had deteriorated in recent

months, but he would recover to enjoy travel to the sea and

beach walks with his family. Son, Remo, continues

leadership of the SELI company which is currently working on

16 TBM tunnel projects, from hard rock to large EPB TBMs, on

five continents.http://www.herrenknecht.com/news/press-section/martin-herrenknecht-becomes-the-first-european-to-receive-the-moles-award-in-the-usa.htmlMARTIN

HERRENKNECHT BECOMES THE FIRST EUROPEAN TO RECEIVE THE “MOLES

AWARD” IN THE USA.  The renowned association of the US heavy

construction industry, “The Moles”, has presented the Schwanau

entrepreneur Dr. Martin Herrenknecht with the “Moles Award

2009”. This makes Martin Herrenknecht the first European and

non-US citizen to be honored with this prize. “The Moles”

award is highly regarded in the heavy construction industry in

the US. New York City, USA / Schwanau, Germany,

February 4, 2009. Dr. Martin Herrenknecht was presented with

the “Moles Award 2009” in New York on January 28, 2009, in

the presence of some 2,000 decision-makers and representatives

of the US heavy construction industry, as well as the

Governor of New Jersey, Jon S. Corzine. Martin

Herrenknecht is the first person living in Europe to receive

this award in the more than 70-year history of the Moles

Association. In addition, the Schwanau entrepreneur was

awarded honorary Moles membership. The Moles Association is

the most important association of decision-makers and

representatives of the US heavy construction industry on the

country’s east coast. The former US President Herbert C.

Hoover is also among those who have been honored with the

Moles Award in the past

|

|

| | |

| TahoeBlue

|

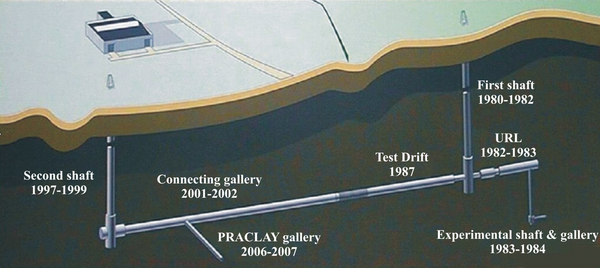

Both Belgium and France have underground

research laboratories and are close to deciding where

their disposal facilities will be located. All of these

countries have worked in partnership with the local

communities and have a high level of support from them for

their projects. http://www.sckcen.be/en/Our-Research/Research-facilities/HADES-Underground-laboratoryHADES -

Underground laboratory The underground

laboratory HADES is the most important research infrastructure

in Belgium for experimental research on the deep geological

disposal of radioactive waste. In 1980, the

Belgian Nuclear Research Centre, SCK•CEN, started the

construction of the underground laboratory. HADES is

situated in Boom clay at a depth of 224 meters and was

extended in different phases: recently, the construction of a

second access shaft (1997-1999) and the building of the

connexion gallery (2001-2002) were completed   ... The Boom clay

formation The underground laboratory HADES is

situated in a Boom clay formation at a depth of about 224

meters. Within the Belgian research programme, the Boom

clay is studied as a reference formation for the geological

disposal of radioactive waste. However, the site where the

future disposal facility will be built has not been chosen

yet. The Boom clay is found on the site in Mol

at a depth between 161 and 264 meters. It reaches a total

thickness of more than 100 meters. Safety assessments

confirm that the Boom clay possesses good qualities, also

thanks to its low hydraulic conductivity and good sorption

properties regarding radioelements. Therefore, it is a

potentially interesting host rock for the disposal of

radioactive waste.

|

|

| | |

| TahoeBlue

|

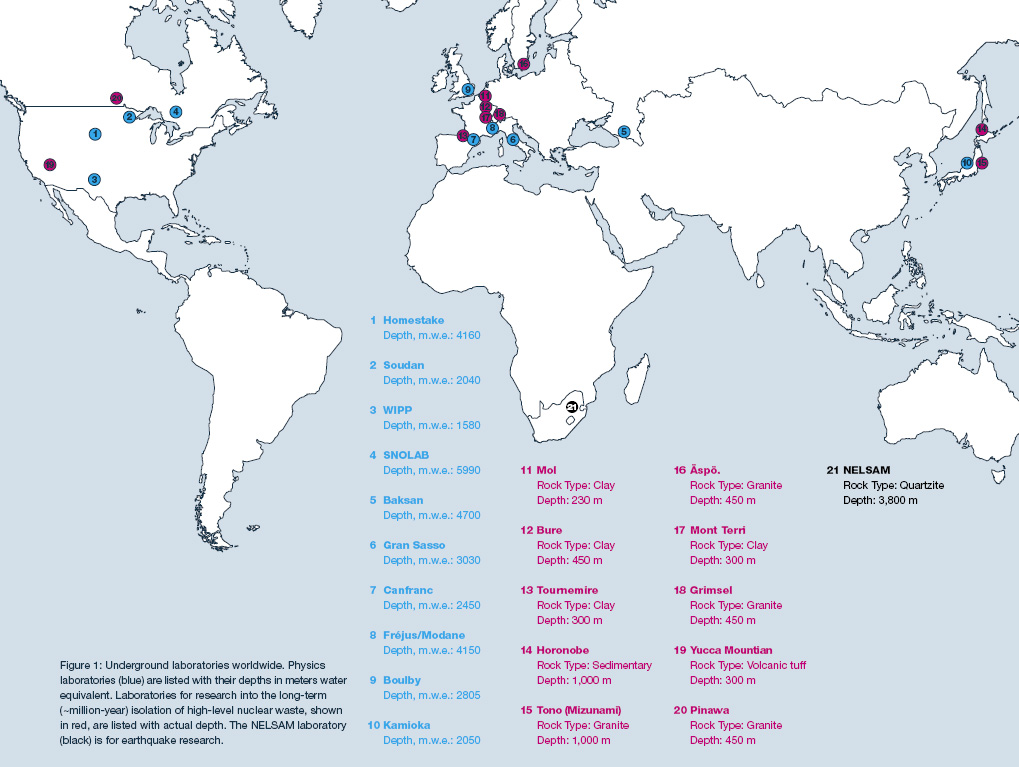

http://www.isrm2011.com/upload/shortcourse/WS5.pdfISRM12

th International Congress on Rock

MechanicsBeijing, China, October 16-21,

2011Networks of Underground Research

Laboratories for International, Inter-disciplinary

InnovationsSynopsis of Workshop Underground

Research Laboratories (URLs) were initially developed in the

1970s in Sweden for thermal and

hydrological responses to

emplacements of spent nuclear materials. Over a dozen URLs

have since been and

established and planned worldwide for

studying coupled

thermal-hydrological-mechanical-chemical-biological

processes.

Similar number of underground facilities has been

developed for physics research, mostly at great

depths

along roadway tunnels and in mine levels. There are

growing interests to use underground

laboratories

for energy and environmental studies and with emphasis in

multi-disciplinary and inter-disciplinary approaches.

This URL workshop will discuss if networking among

underground laboratories can be further developed from state

of knowledge gained from past experience, current status of

operation, and evolving plans. The preliminary agenda and

topics to be discussed are given in the following

table. http://articles.cnn.com/2010-11-12/world/finland.nuclear.waste_1_nuclear-waste-disposal-canisters?_s=PM:WORLD Finland's nuclear waste bunker built to last

100,000 years Finland's nuclear waste bunker built to last

100,000 yearsNovember 12, 2010|By Matt Ford for

CNN It's one of the great questions of our age: What to

do with nuclear waste? It's challenging, not just

because radioactive material is highly toxic, but because

really engaging with the problem forces us to confront

unimaginable timescales. But in Finland they

believe they have found a solution, with the world's first

permanent nuclear-waste repository -- "Onkalo" -- a huge

system of underground tunnels that is being hewn out of solid

rock and must last at least 100,000 years. "It is

our law that we have to dispose of our nuclear waste within

Finland's borders," Timo Seppala, from Posiva, the company

constructing the site, told CNN.

|

|

| | |

| TahoeBlue

|

http://www.wadenelson.com/gasbuggy.htmlNuclear

explosion shook Farmingtonby Wade H.

Nelson There was no mushroom cloud, but on December

10, 1967, a nuclear bomb exploded less than sixty miles from

Farmington New Mexico. Today, all that remains at the site is

a plaque warning against excavation and perhaps a trace of

tritium in your milk. The explosion was part of

Operation Plowshare, a program conducted by the Atomic Energy

Commission (AEC) to explore peaceful uses of atomic bombs. AEC

scientists proposed using nuclear weapons as high-powered

dynamite in a variety of "nuclear landscaping" projects. The

most ambitious Plowshare proposal suggested setting off as

many as 300 hydrogen bombs to blast a newer, larger canal

across the Isthmus of Panama. The goal of the

Farmington blast, code-named Gasbuggy, was to see if a smaller

underground nuclear explosion would stimulate the release of

natural gas trapped in dense shale deposits. Gasbuggy

called for a 29 kiloton warhead to be set off four thousand

feet underground in an existing, low-productivity gas

well. Participants in Project Gasbuggy included the AEC,

the Bureau of Mines and the El Paso Natural Gas Company

(EPNG). Ground zero was seven and a quarter miles south on

Forest Road 537, south off State Highway 64, in the Carson

National Forest. ... Nation-wide, it was hoped

nuclear stimulation of gas wells might result in the recovery

of as much as ten times the amount of natural gas as was then

being recovered and help relieve the nation’s energy

crisis. The

Gasbuggy blast created an underground cavern approximately 160

feet in diameter by 333 feet tall --imagine putting

an oversized football field on a stick like a popsicle,

pushing it 3800 feet down into solid rock, and twirling it. A

few seconds after the explosion the molten glass-lined cavern

collapsed, creating a chimney filled with rubble and debris.

Geologists later estimated that fractures extended out from

the cavern a few hundred feet in all directions. http://en.wikipedia.org/wiki/Operation_PlowshareProject

Plowshare was the overall United States term for the

development of techniques to use nuclear explosives for

peaceful construction purposes... Other proposals

involved blasting underground caverns for water, natural

gas, and petroleum storage. Serious consideration was also

given to using these explosives for various mining

operations. One proposal suggested using nuclear blasts to

connect underground aquifers in Arizona. Another plan involved

surface blasting on the western slope of California's

Sacramento Valley for a water transport project

|

|

| | |

| TahoeBlue

|

Norway Doomsday seed vault bunker

videohttp://blog.2012pro.com/2012/2012-underground-survival-bunkers-%E2%80%93-norwegian-politician-speaks-about-surviving-global-catastrophe-in-the-government-bunkers-in-norwayThe

person who wrote this message to us did so under their own

name (which we have checked), and enclosed a number of

photographs of them with the Prime Minister of Norway and

(separately) with Benazir Bhutto. We are certain of their

bona fides, but you will understand that we cannot reveal

their real name or publish any photos without consent.

The

content of this message, if true, could hardly be more

important.... All the sectors and arks are

connected with tunnels and have railcars that can take you

from one ark to the other. This is so that they can be in

contact with each other. Only the large doors separate them so

that the sectors are not compromised in any matter. http://www.ngi.no/en/NGI

worldwide - NGI is an internationally actor within our

fields of expertise. Approximately 30 per cent of NGIs work

is on projects outside Norway.NGI Inc., NGI's

daughter company in Houston, Texas, contributes to

enhanced contact with the international oil and gas

industry Our services are applicable for almost all

facets of civil engineering. Examples are foundations for

buildings and large structures such as bridges, railways and

road building, water supply and sewage systems, tunnels and

rock caverns, coastal engineering and embankments and

rockfill dams. We cover the whole planning process from

feasibility and impact studies to detailed design and

follow-up at the construction

site. State-of-the-art NGI did the foundation

engineering for the new Oslo Opera and for the neighbouring

immersed tunnel crossing in Bjørvika. The innovative

tunnel was constructed by elements floated into position and

lowered onto a pre-made channel on the seabed, and then

assembled. Our

knowledge has been used to develop the Q-method - a tool which

is used internationally to classify rock masses and assess

permanent rock support in tunnels and caverns.

Since its introduction in 1974, the Q-method has been updated

several times. This empirical method is based on data from

existing tunnels around the world. Our expertise also includes

numerical modelling and recommendation of stabilizing

measures. NGI has a world-class geo-laboratory, with

experienced personnel. http://thelistcafe.com/top-10-fascinating-underground-laboratoriesTop

10 Fascinating Underground LaboratoriesBuckle up

as we go for a ride inside the earth and take a look at what

can be achieved when we look down long enough for the Earth to

get our attention and whisper her secrets.

|

|

| | |

| TahoeBlue

|

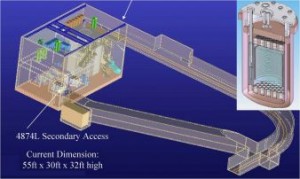

http://www.sanfordundergroundlaboratoryathomestake.org/ Dr. Ray Davis inspects his neutrino detector

under construction Dr. Ray Davis inspects his neutrino detector

under construction in the Homestake gold mine.

(1965) A laboratory 4,850 feet underground in the

Homestake gold mine in Lead, South Dakota, helped start a

revolution in physics. Dr. Ray Davis installed a

neutrino detector in Homestake in 1965. Neutrinos are

subatomic particles produced by fusion in stars, and over the

course of three decades, the Davis experiment led to the

discovery that the neutrinos produced in our sun change type,

or "flavor," on their way to earth. The change in flavor meant

neutrinos had to have at least a wisp of mass -- a wisp that

required a significant change in the Standard Model of how the

universe works. http://www.sanfordundergroundlaboratoryathomestake.org/index.php?option=com_content&view=article&id=140&Itemid=42 Depth is Homestake's crucial asset. A thick

layer of the earth's crust can stop most cosmic radiation.

Ultra-sensitive detectors in deep, quiet labs, where they are

protected from surface noise, can probe the universe's

best-kept secrets. Experiments planned for the new Homestake

lab include bigger, more sophisticated neutrino detectors.

Other detectors will look for even more elusive phenomena such

as dark matter, proton decay and neutrinoless double-beta

decay. ... Today the deepest, largest underground

laboratories are in Japan, Canada and Italy, but those labs

have waiting lists for experiments. A deep lab at

Homestake could more than double the world’s inventory of

underground lab space. http://www.ars.usda.gov/research/publications/publications.htm?seq_no_115=217575Title:

Industrially useful microorganisms isolated from deep

underground science and engineering laboratory (DUSEL) mine

biofilms Publication Date: November 4,

2007 ... The Deep Underground Science and Engineering

Laboratory (DUSEL) mine provides one of the most promising

sources for microorganisms to date. These microorganisms

have systematically evolved from organisms introduced from the

surface to deep below ground level by humans and animals

during mining and through water run off into the mine.

The microorganisms in this deep mine have been

subjected to temperatures in excess of 100ºC, little external

radiation, and in many cases have used lignocellulosic

material as a food substrate. The wood in these mines is

covered with biofilms that have evolved to survive the harsh

environment. It is the objective of this team at South Dakota

School of Mines and Technology (SDSM&T), South Dakota

State University, and United States Department of Agriculture,

National Center For Agricultural Utilization Research,

Agricultural Research Service to isolate and characterize

anaerobic and aerobic bacteria and fungi that are capable of

utilizing the lignocellulose at high temperature to produce

biofuels and valuable chemical feedstock for use in industrial

applications and to foster this new bioindustrial

infrastructure with profitable co-products for chemical

feedstocks, animal feed, and better production of starch and

cellulosic biofuels. The microorganisms will be

screened in high-throughput for growth on cellulose and

hemicellulose. They will be examined using automated

integrated robotic paradigms for combinations that give

optimum growth on recalcitrant lignocellulosic substrates and

for maximum ethanol production. ... New strains will

be engineered in high-throughput via mass transformation of

full length gene libraries to introduce these new DUSEL

gene sets into traditional ethanologenic microorganisms for

improved cellulases and hemicellulases as well as new genes

for metabolic corrections to allow utilization of pentose as

well as hexose sugars in fermentation processes.

|

|

| | |

| TahoeBlue

|

http://permafrosttunnel.crrel.usace.army.mil/Take a Virtual Tunnel Tour. See

permafrost up close; learn about ice wedges, ice lenses, and

other permafrost features; see bones of the Pleistocene

bison, mammoth, and horse 25,000 year old Bacteria found in

Permafrost here have been revived Significant numbers of viable

ancient microorganisms are known to be present within the

permafrost. They have been isolated in both polar regions

from the cores up to 400 m deep and ground temperatures of

−27°C. The age of the cells corresponds to the longevity of

the permanently frozen state of the soils, with the oldest

cells dating back to ~3 million years in the Arctic, and ~5

million years in the Antarctic. They are the only life

forms known to have retained viability over geological time

Permafrost bacteria may slow down

ageing: scientists

January 17, 2012

Russian

scientists claimed that a hardy type of bacteria recently

discovered in the permafrost of Siberia could help slow down

the ageing process.

The species of bacteria -- given

the name Bacillius F -- was found in laboratory tests to have

shown signs of slowing down the process of ageing on mice, the

Russian Academy of Sciences (RAN) said.

The Siberian

branch of the RAN said Bacillius F lags 3 million years behind

similar bacteria in evolutionary terms, according to the

characteristics of proteins and some other factors.

The United States Army The United States Army maintains and

operates a unique research facility near Fairbanks,

Alaska, known as the CRREL Permafrost Tunnel Research

Facility. CRREL is an acronym for the U.S. Army's Cold

Regions Research and Engineering Laboratory, part of the

U.S. Army Corps of Engineers Engineer Research and Development

Center. The Permafrost Tunnel was excavated from

1963–1969 for the study of permafrost, geology, ice science,

and the mining and construction techniques specific to

permafrost environments. The story of the tunnel

excavation is found in the Excavation Methods page of this Web

site. Fascinating features of the tunnel are described in the

Soil and Rock and Paleontology sections, and are shown during

the Virtual Tunnel Tour. The Permafrost Tunnel offers a

unique research platform for scientists and engineers who wish

to study a frozen environment over 40,000 years

old.Researchers at the CRREL Alaska Research

Office Fairbanks, Alaska, maintain and manage the Permafrost

Tunnel Research Facility and offer support for scientific

research projects.

|

|

| | |

| TahoeBlue

|

Top 10 Fascinating Underground

LaboratoriesBuckle up as we go for a ride inside

the earth and take a look at what can be achieved when we look

down long enough for the Earth to get our attention and

whisper her secrets. 10 SNO and SNOLAB - Sudbury

Ontario Canada - Enter the Sudbury Neutrino

Observatory (SNO for short) is 2km (6,800 feet) deep in

the ground ( a mile plus 1514 feet) in Ontario,

Canada. 9 DUSEL - Lead South Dakota - The Deep

Underground Science and Engineering Laboratory (DUSEL) is a

futuristic underground project that is on the table and the

National Science Foundation is very excited by the prospect.

8 Aquarius Reef base - Florida Keys

Florida 7 Kola Super Deep Borehole Kola

Russia 6 Svalbard Seed Bank - Spitsbergan Island

Norway 5 Lake Vostok - Vostok Station

Antartica 4 Super Kamiokande - Hida Japan -

3,281 feet (1100m) below ground Laboratory. It is directly

under Mount Kamiokako, (kah-me-oh-cake-oh) near the Japanese

city of Hida 3 Gran Sasso - Gran Sasso Mountains

Italy - Gran Sasso National Laboratory has huge

underground facilities, so huge that they are in fact the

biggest underground laboratory in the World. 2

IceCube Nutrino Observatory - Antartica - The IceCube

project uses the natural ice of the South Pole instead of

water. A string of 70 (and later 86) holes are drilled into

the ice one and one half miles deep. 1 Cern -

Geneva Switzerland - CERN is the European Council for

Nuclear Research. (The letters make sense when said in French)

located 110 meters below ground in Northwest Geneva. They have

built a particle accelerator and have succeeded in crashing

two protons together at 99.99% of the speed of light. The CERN

organization is the largest gathering of scientists on the

planet incorporating the efforts of over 7,900 of them from

580 universities and over 80 nationalities.

|

|

| | |

| TahoeBlue

|

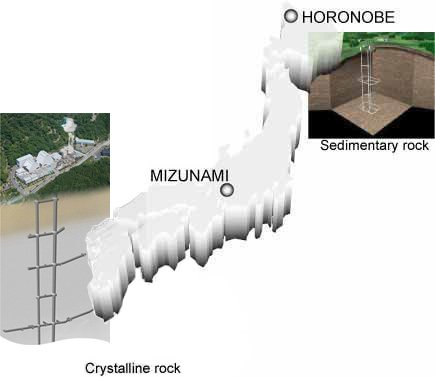

http://www.jaea.go.jp/04/tono/miu_e/Tono

Geoscience Center (TGC), Japan Atomic Energy Agency (JAEA) has

been carrying out a wide range of geoscientific research in

order to build a firm scientific and technological basis for

geological disposal. One of the major components of

the ongoing geoscientific research program is th e Mizunami

Underground Research Laboratory (MIU) Project in the Tono

area, central Japan. Two 1,000m deep shafts and several

drifts will be excavated for geoscientific research and

applicability of engineering techniques will be

estimated. JAEA has been carrying out geoscientific

research at two locations: the location for

investigation of crystalline rock is in Mizunami City, Gifu

Prefecture; the location for investigation of

sedimentary rock is at Horonobe, Hokkaido.  Master Plan of the Master Plan of the

Mizunami Underground

Research Laboratory Project

|

|

| | |

| TahoeBlue

|

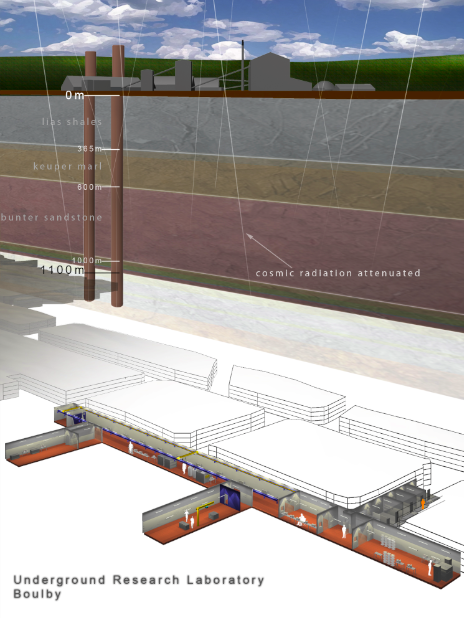

http://www.hep.shef.ac.uk/research/dm/boulby/boulby.phpBoulby

Underground Laboratory: the UK's deep underground

science facility, located 1100m below ground in Boulby

Mine on the North East coast of England. Boulby is the

home to the ZEPLIN-III and DRIFT-II Dark Matter search

projects and various other 'low background', geoscience

and environmental science studies.  There is a huge network of roadways and

caverns underground at Boulby with over 1000kms of tunnel

having been excavated since beginning of mining operations in

1968. There is a huge network of roadways and

caverns underground at Boulby with over 1000kms of tunnel

having been excavated since beginning of mining operations in

1968. The salt and potash seams are left over from the

evaporation of an ancient sea (the Zechstein Sea) over 200m

years ago. The main roadways and long-lasting caverns are cut

into the rock-salt layer. Within the salt caverns UK

scientists and engineers have built a series of laboratories.

With over 1100m of rock overhead reducing cosmic rays by a

factor 1 million - and with the surrounding rock salt being

low in natural background radioactivity - the laboratories

make an ideal site for ultra-low background and deep

underground science projects. http://en.wikipedia.org/wiki/BoulbyBoulby

is a village in the borough of Redcar and Cleveland and the

ceremonial county of North Yorkshire, England. It is

located just off the A174 near Easington, and 1 mile west of

Staithes. ... To the north-west of the village is Boulby

Quarries a Site of Special Scientific Interest designated due

to its geological interest. Boulby is also home

to Cleveland Potash at Boulby mine - Europe's

second-deepest mine, where potash and rock salt is mined 2

kilometres (1.2 mi) underground.

|

|

| | |

| TahoeBlue

|

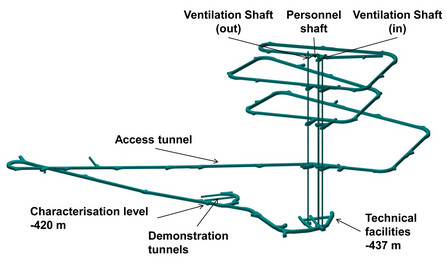

In Europe, Finland is developing an

underground characterisation facility at Olkiluoto, known as

the ONKALO, which has now reached a depth of about 320m.

If ONKALO confirms that the site meets all the safety case

criteria for the development of a repository, a facility will

be developed at the site with a planned commencement of

disposal operations around 2020. http://www.posiva.fi/en/research_development/onkaloONKALO

One element of the site investigations conducted at

Olkiluoto is the excavation of the underground rock

characterisation facility (ONKALO) that will be extended to

the final disposal depth (approximately -400m). ONKALO

aids in collecting the further data needed for the application

for the construction licence that will be submitted in

2012. The bedrock is studied with methods from geology,

hydrology and geochemistry. In addition to facilitating

bedrock research, ONKALO also provides an opportunity to

develop excavation techniques and final disposal

techniques in realistic conditions. Later, the ONKALO

facilities can be put into use when building and using the

repository. Posiva started to construct ONKALO in

2004. Research has been conducted there since the

beginning of its construction. ONKALO consists of one

access tunnel and three shafts: a personnel shaft and two

ventilation shafts. The slope of the tunnel is 1:10. It is 5.5

m wide and 6.3 m high http://www.posiva.fi/en/research_development/onkalo/onkalo-animation/

|

|

| | |

| TahoeBlue

|

http://english.peopledaily.com.cn/90001/90776/90881/7229358.htmlChina's

1st deep underground lab now operational for dark

matter14:29, December 13,

2010China's first deep underground laboratory

was formally put into service in Jinpin hydropower station in

Sichuan Province on Dec. 12, which means China now

possesses an independent cutting-edge underground scientific

research and experimental platform in physics. Cheng

Jianping, director of the project, said the

lab is currently the deepest underground lab in the world with

vertical rock coverage of 2,400

meters.Experts from the project said the

deep underground laboratory is of great importance for

research of major leading basic research topics, including

dark matter, particle physics, nuclear physics, neutrino

physics, astrophysics and cosmology, and is a sound

environment for research of rock mechanics, earth structure,

ecology, low-level radioactive materials and nuclear radiation

detection for environmental protection. Experts from

the China Institute of Atomic Energy, Tsinghua University,

Sichuan University and the Ertan Hydropower Development

Company formed a cooperation group to conduct dark matter

detection experiments using a germanium detector made by

germanium crystal material with the highest purity in the

world. The lab’s first research on dark matter is expected to

be completed in 2011. http://asia.iop.org/cws/article/news/47110the

Jinping Underground Laboratory is situated some 2.4 km

underneath the Jinping Mountain in Sichuan

province. ... As the lab is underneath several

kilometres of marble and sandstone, spurious signals from

cosmic rays are blocked, making it an ideal surrounding in

which to search for dark matter – the mysterious

substance that accounts for about 80% of the matter in the

universe. The Jinping lab will initially house two experiments

in that quest. Already installed is the China Dark Matter

Experiment, which is a collaboration of about 30 physicists

led by Tsinghua University that will use a germanium detector.

http://wwwgerda.mppmu.mpg.de/symp/03_Yue.pdfChina

JinPing underground Laboratory (CJPL) and China Darkmatter

Experiment (CDEX)

|

|

| | |

| TahoeBlue

|

http://www.globalsecurity.org/wmd/world/russia/yamantau.htmYamantau

Beloretsk-15 Beloretsk-16 Alkino-2 ?  Starting in the Brezhnev period, Russia

has been pursuing construction of a massive underground

facility at Yamantau Mountain and the city of Mezhgorye Starting in the Brezhnev period, Russia

has been pursuing construction of a massive underground

facility at Yamantau Mountain and the city of Mezhgorye

(formerly the settlements of Beloretsk-15 and Beloretsk-16).

The complex, reportedly being built by tens of thousands of

workers, is said to cover an area of up to 400 square miles,

the size of the Washington area inside the

Beltway. The exact location of this large

facility is uncertain, and given its reported size it may

span as much as an entire degree of latitude and longitude. It

is apparently located near the the Zlatoust-36/Yuryuzan

nuclear weapons production plant and the Yuryuzan

national-level nuclear weapons storage facility. The Yaman-Tau

Gory [mountains] range is centered at 52�25'N 56�45'E, while

the peak of Yamantau Gora [mountain] is at 54�15'19"N

58�06'11"E. The town of Beloretsk is located at 53�58'N

58�24'E, though NIMA does not include a listing for Mezhgorye.

This facility may be synonymous with "Alkino-2" since the town

of Al'kino is nearby at 55�05'N

58�04'E. ... The New York Times quoted Russian

officials describing the underground compound variously as a

mining site, a repository for Russian treasures, a food

storage area, and a bunker for Russia's leaders in case of

nuclear war. "The (Russian) Defense Ministry declined to

say whether Parliament has been informed about the details of

the project, like its purpose and cost, saying only that it

receives necessary military information," according to the New

York Times. Satellite photographs of Yamantau

Mountain show continued digging at the "deep undergound

complex" and new construction at each of the site's

above-ground support areas. Judging from satellite photos

and other intelligence, US officials are fairly confident

that the Russians are building an underground command bunker

and communications installation. But "... the

Russians are not very interested in having us go in there," a

senior American official said in Washington. "It is being

built on a huge scale and involves a major investment of

resources. The investments are being made at a time when the

Russians are complaining they do not have the resources to do

things pertaining to arms control." http://www.bibliotecapleyades.net/sociopolitica/esp_sociopol_underground16.htmWhat's

Going On in The Yamantau Mountain

Complex?Today, Russia may be conducting nuclear

deception on a far vaster scale beneath Yamantau Mountain,

where it has dug out a gigantic underground military complex

designed to withstand a sustained nuclear assault. A U.S.

intelligence source was quoted as saying that the Yamantau

complex is but one of some 200 secret deep underground nuclear

war-fighting sites in Russia, many of which have been

significantly upgraded over the past six years at a cost of

billions of dollars. ... In 1998, in a rare

public comment, then-Commander of the U.S. Strategic Command

(STRATCOM) Gen. Eugene Habinger, called Yamantau "a

very large complex -- we estimate that it has millions of

square feet available for underground facilities. We don't

have a clue as to what they're doing there."It is

believed to be large enough to house 60,000 persons, with a

special air filtration system designed to withstand a nuclear,

chemical or biological attack. Enough food and water is

believed to be stored at the site to sustain the entire

underground population for months on end. "The only

potential use for this site is post-nuclear war..."

--- Rep. Roscoe Bartlett http://en.wikipedia.org/wiki/Mount_YamantauMount

Yamantau (Russian: гора Ямантау) is in the Ural Mountains,

Bashkortostan, Russia. The name means bad (evil) mountain in

the Bashkir language (Яман тау). It is also known as Mount

Yamantaw[citation needed]. It stands at 1,640 metres (5,381

ft) and is the highest mountain in the southern Urals. Along

with Kosvinsky Mountain (600 km to the north), it is suspected

by the United States of being a large secret nuclear facility

and/or bunker.[1] The closed military town of Mezhgorye

(Russian: Межгорье) is situated nearby. As late as 2003,

Yamantaw was not yet fully operational.[1] Large

excavation projects have been observed by U.S. satellite

imagery as recently as the late 1990s, during the time of

Boris Yeltsin's government after the fall of the Soviet

Union.[1] Two garrisons, Beloretsk-15 and Beloretsk-16, were

built on top of the facility, and possibly a third, Alkino-2,

as well, and became the closed town of Mezhgorye in 1995. They

are said to house 30,000 workers each. Repeated U.S. questions

have yielded several different responses from the Russian

government regarding Mount Yamantaw.[2] They have said it is a

mining site, a repository for Russian treasures, a food

storage area, and a bunker for leaders in case of nuclear

war ... Russian newspapers reported in 1996 that it

is a part of the "Dead Hand" nuclear retaliatory command

structure.

|

|

| | |

| TahoeBlue

|

http://www.deepscience.org/contents/facilities.shtml Facilities for Deep

Science Facilities for Deep

ScienceThe 21st century exerts increasing demands

to go underground. Expanding and developing populations put

growing pressure on surface space, driving mass transit

systems, hydroelectric plants, energy storage, waste disposal

facilities and a host of other systems underground. The

depletion of shallow mineral and energy resources sends

prospectors ever deeper in search of essential raw materials

and new sources of energy. Yet despite the demand for

subsurface space and resources, major engineering obstacles to

underground use remain.

|

|

| | |

|

|

| TahoeBlue

|

http://www.globalsecurity.org/military/facility/range-navy.htm http://www.globalsecurity.org/military/facility/socal.htmSouthern

California (SOCAL) Offshore Complex http://www.globalsecurity.org/military/facility/socal.htmSouthern

California (SOCAL) Offshore Complex The SOCAL Offshore Complex also includes

W-291 and Marine Corps Base (MCB) Camp Pendleton. The

complex is located along the coast and in the waters adjacent

to Southern California from Santa Barbara to Baja

California. The complex is composed of the

following instrumented areas: ■Fleet Training Area (FLETA)

■San Clemente Island Underwater Range/Operating Area

(SCIUR/OPAREA) 3803 ■Shore Bombardment Area (SHOBA)

■SOCAL ASW Range (SOAR) ■Range Electronic Warfare

Simulator (REWS) ■Large Area Tracking Range (LATR)

■Camp Pendleton Amphibious Assault

Operations/Artillery/Aircraft Bombing and ■Strafing Range

(R-2503) ■Shipboard Electronic Systems Evaluation Facility

(SESEF) http://www.scisland.org/aboutsci/score-development-history.pdfSouthern

California Offshore Range (SCORE)Development History

(1981-2007) The San Clemente Island Range Complex

(SCIRC) is the cornerstone of the tactical training ranges for

the Southern California Operations Area (SOCAL).

SOCAL supports the largest concentration of naval

forces in the world. The SCIRC land, air, and sea ranges

provide the U.S. Navy, U.S. Marine Corps, and other military

services, space and facilities which they use to conduct

readiness training, and test and evaluation

activities. ... THE SCORE MISSION The mission

of SCORE is to improve the combat readiness of Pacific Fleet

air, surface, and submarine units in all warfare areas

providing instrumented operating areas and associated

facilities to support training exercises. Ancillary

missions include support for evaluations of equipment and/or

tactical concepts developed to support Navy programs. Since

its inception in 1985, the use of SCORE can be directly

related to the U.S. Navy’s success in world conflicts, and the

high state of readiness that the Department of Defense enjoys

today.

|

|

| | |

| TahoeBlue

|

The Moles Association is the most important

association of decision-makers and representatives of the US

heavy construction industry on the country’s east coast. The

former US President Herbert C. Hoover is also among those

who have been honored with the Moles Award in the

past http://themoles.info/organization/They

have been called “crazy men in a crazy industry” who gamble

their fortunes and reputations against the challenges they

meet. Often working underground, they change the face of

the earth, building tunnels, dams, highways and bridges. They

are defined as heavy construction workers. In